Introduction of Corrugated Transparent Roof Panel Types

ZXC Corrugated clear roofing sheets are widely used in residential and commercial buildings for their good durability, lightness and light transmittance. The following is a detailed description of the three types of corrugated transparent roof panels, including materials, advantages, application scenarios, installation methods, etc.

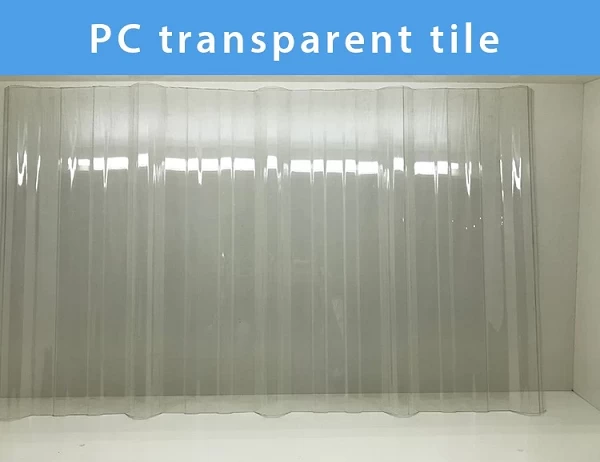

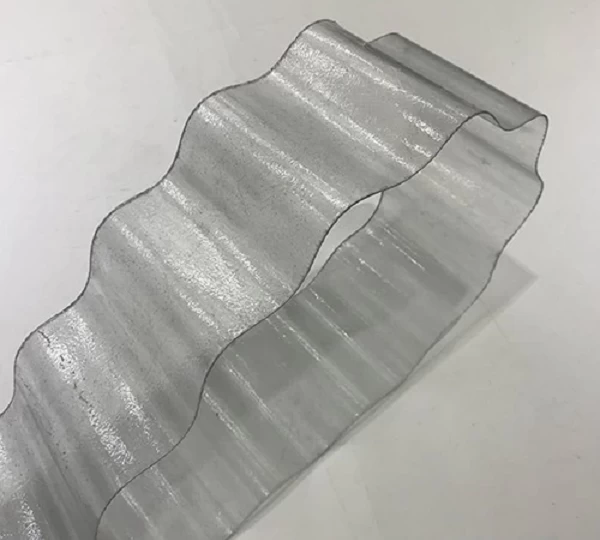

Polycarbonate | new clear roofing sheets manufacturer

Features: Strong impact resistance, high temperature resistance, excellent weather resistance and UV resistance.

Advantages: Can withstand high and cold weather, and is not easy to age or turn yellow after long-term use.

Application: Suitable for roofs of greenhouses, balconies, carports, stadiums and commercial buildings.

Polyvinyl chloride (PVC) | corrugated pvc roof panel on sale

Features: Lightweight, easy to cut and install, suitable for short-term and temporary use.

Advantages: Relatively low cost, but slightly inferior to polycarbonate in durability.

Application: Mostly used for roofs of sheds, temporary drying rooms and light buildings.

Fiberglass | corrugated clear roofing sheets price

Characteristics: Good light transmittance and strength, but relatively brittle.

Advantages: Can provide good thermal insulation.

Applications: Commonly used in skylights, greenhouses, carports and some industrial buildings.

Installation precautions

Frame preparation: Make sure the mounting bracket is stable and can withstand the weight of the material and wind pressure.

Gap reservation: According to the manufacturer's instructions, set appropriate overlap and fixed gaps to cope with expansion and contraction caused by temperature changes.

Fixing method: Use specified screws and accessories to ensure that there is no leakage. Check the tightness of each connection point to increase durability.